When mixing welding gases, the highest accuracy can be important for quality and/or costs. This is where the gas mixers from LT GASETECHNIK show their special strength.

Panel production plants and profile welding with gantry welding machines use gas mixtures of Ar, CO2, and Ar, CO2, He. Helium, in particular, is an expensive and scarce noble gas in which the highest mixing precision quickly pays off. The LT gas mixers used for these projects guarantee a deviation of ≤ ± 0.2 vol.%. In contrast to the previously used gas mixers of a market competitor with ± 2 vol.% deviation, this means an improvement of 90%.

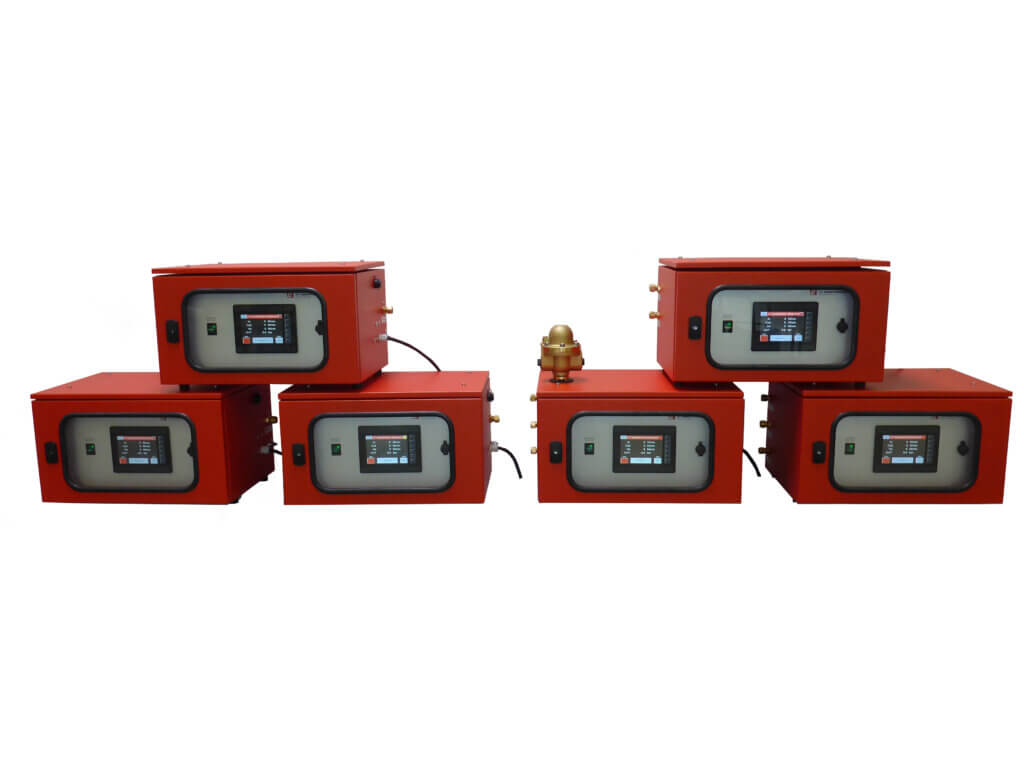

In this project, the gas mixers installed on the portals were connected to the machine control system with Beckhoff interface. In this way, the respective welding machine can select the appropriate recipe and the gas mixer sets the required gas mixture fully automatically. This not only saves money, but also always produces quality with the right welding gas.

Of course, this type of gas mixer can also permanently document the individual gas consumption and analyze and document the mixed gas quality.

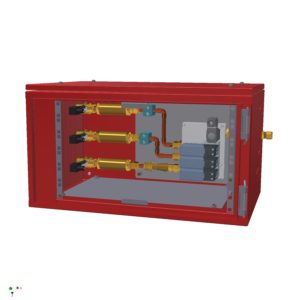

3D representation of gas flow in the laser hybrid gas mixer for Ar, CO2, He with a power of 2… 50 l/min

3D representation of gas flow in tandem MAG gas mixer for Ar CO2 with a capacity of 30… 100 l/min

Do you have tasks related to arc welding or laser welding that require a high amount of gas mixture, require the highest gas mixture quality and/or work with recipe selection? We are happy to advise you: info@lt-gasetechnik.com