For our customers from the Machine and Plant Engineering we manufacture installations for gas- and mixed gas-supply of our customer’s plants. Since many years we manufacture installations, in particular for the production of forming gas, for our customers from the mechanical and plant engineering as well as from industrial furnace industry.

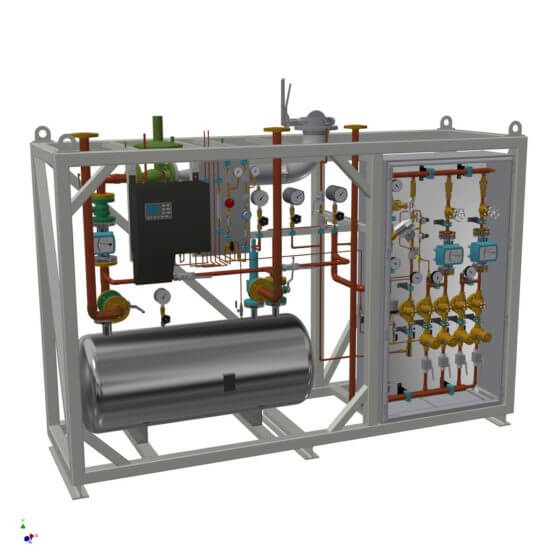

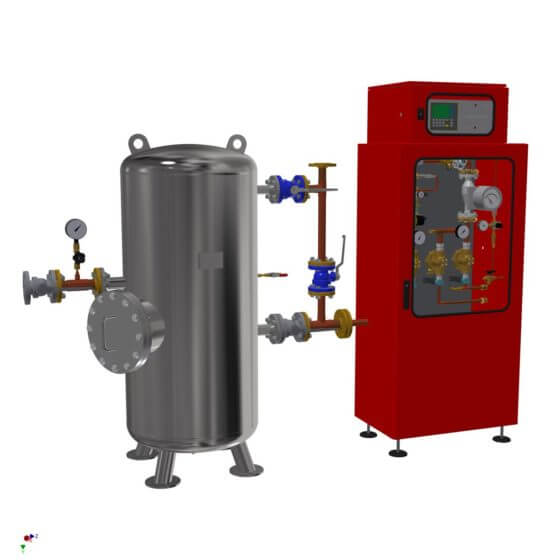

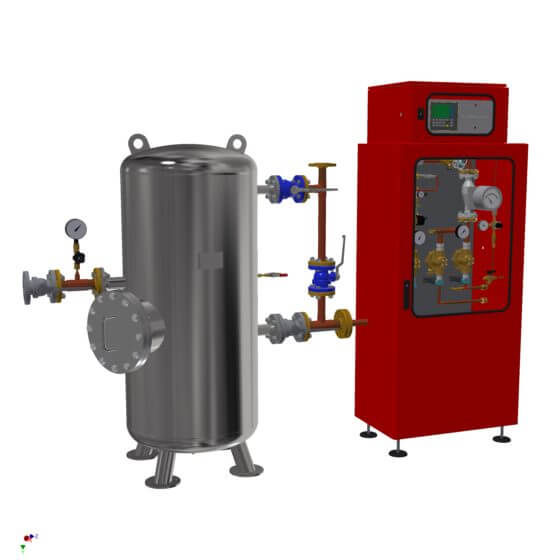

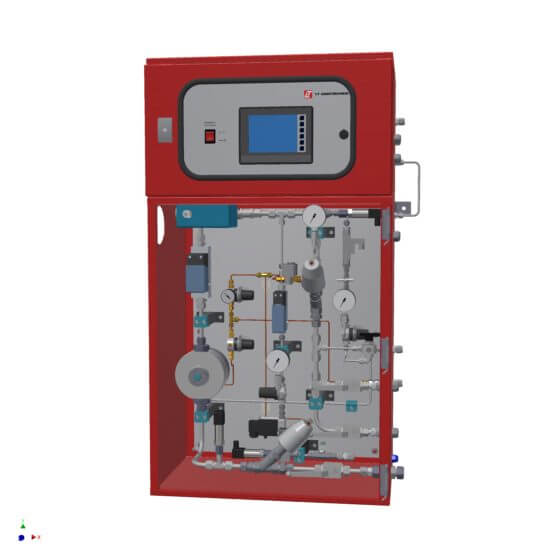

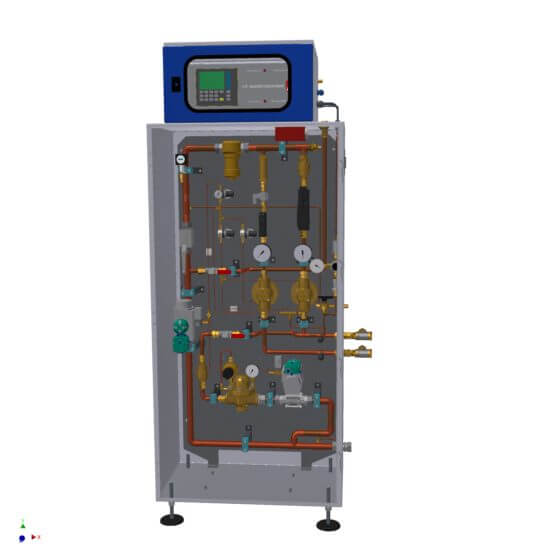

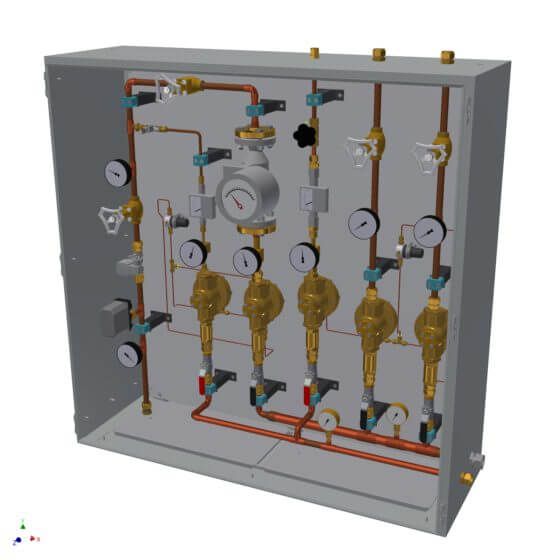

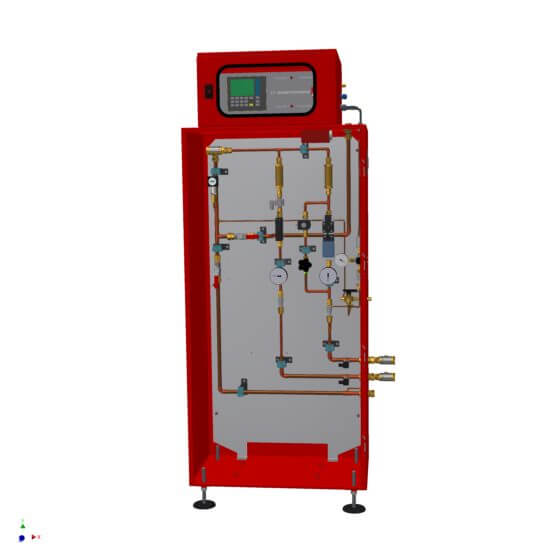

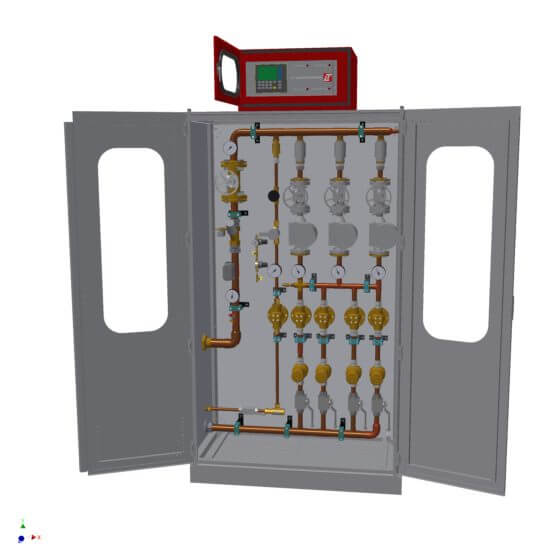

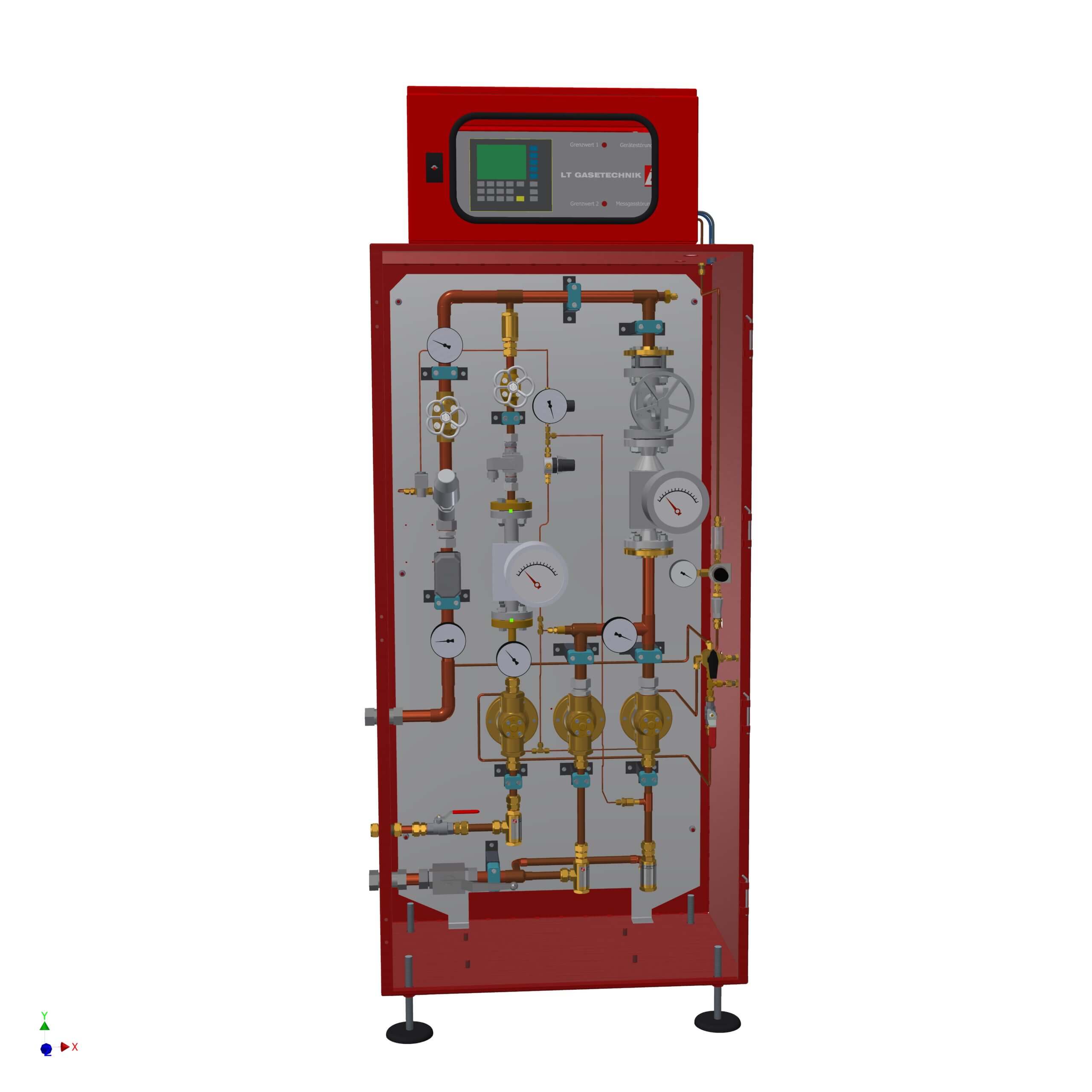

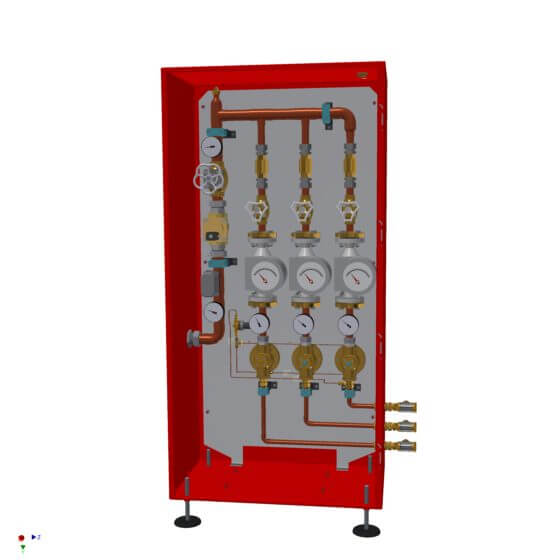

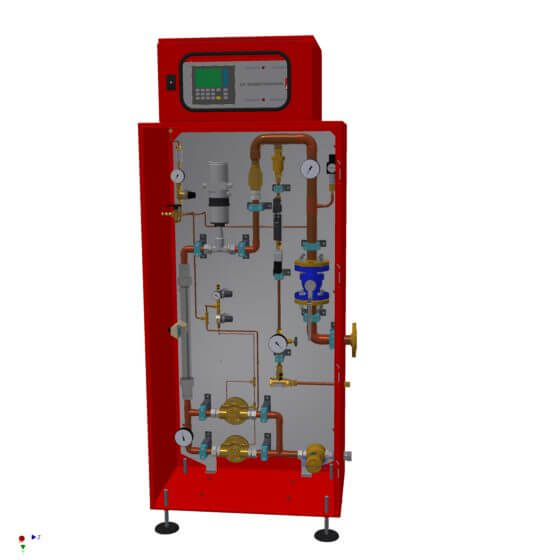

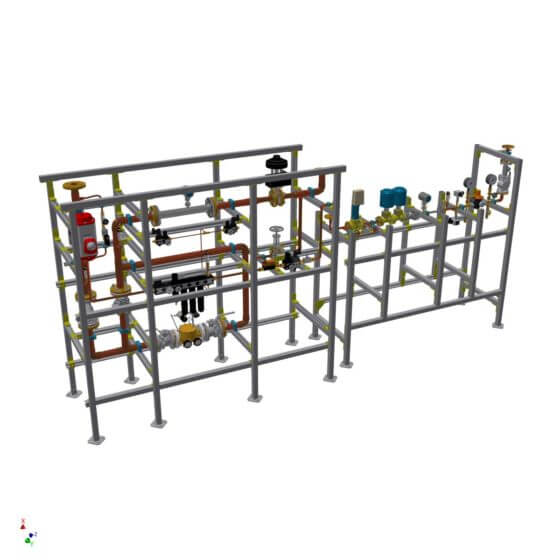

Standard gas mixers for forming gas or protective gas production from cracking gas or H2/N2 with H2 shares of up to 25% have a capacity of 200, 300, 500 or 600 m³/h, with or without tank in customized sizes such as 500 m³/h or 1,000 Nm³/h. These systems are usually built on a steel frame with integrated control and analysis technology.

Project examples from Machine and Plant Engineering

- H2/N2 atmosphere for reaction furnaces 5.0 .. 25.0% H2 in N2 with 200 m³/h; control system, signal exchange and set point via Ethernet, with analysis system

- Individual designed and manufactured gas mixers and gas mixing plants

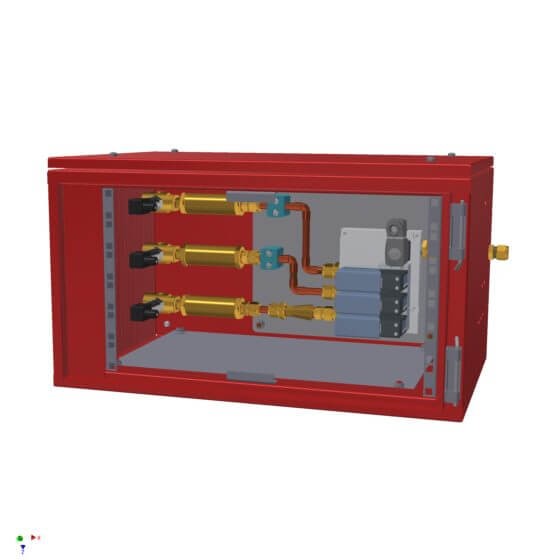

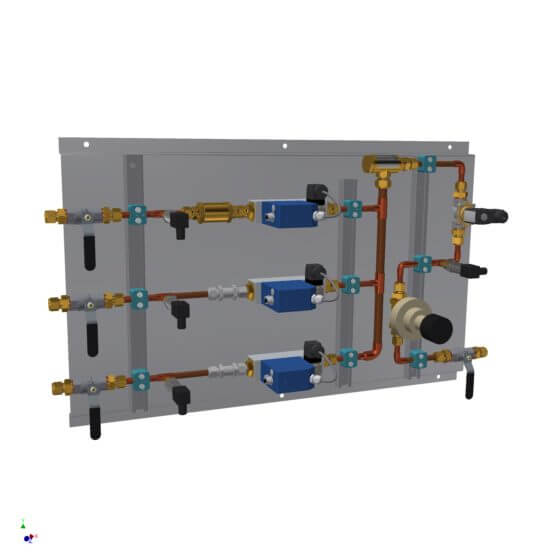

- Standard gas mixer for Arg / CO2 in capacities from 25 to 500 m³/h, with or without tank. The permanent documentation of the mixed gas quality is ensured by analysis technology with integrated data logger. The data is available via LAN, Bluetooth or USB interface.

- Equipment of welding machines with gas supply routes

Please ask for our extensive reference list!