Availability and accuracy for automotive suppliers

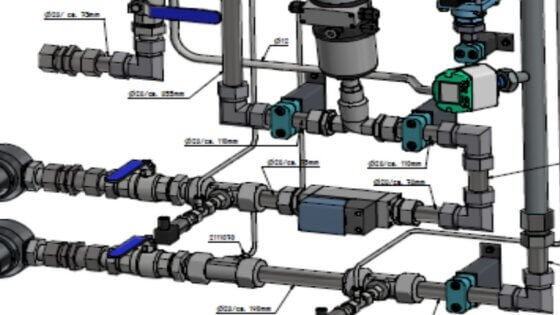

https://www.lt-gasetechnik.de/wp-content/uploads/2020/05/gasmischer-1024x242.jpg 1024 242 Alexander Hanf Alexander Hanf https://secure.gravatar.com/avatar/f89f4d10a36f5d89cef53cf152aa4130?s=96&d=mm&r=gOur customer manufactures innovative lighting products for the automotive industry and attaches great importance to availability and gas mixture accuracy. Various gas mixtures are required for production. Z. B.: Argon…

read more