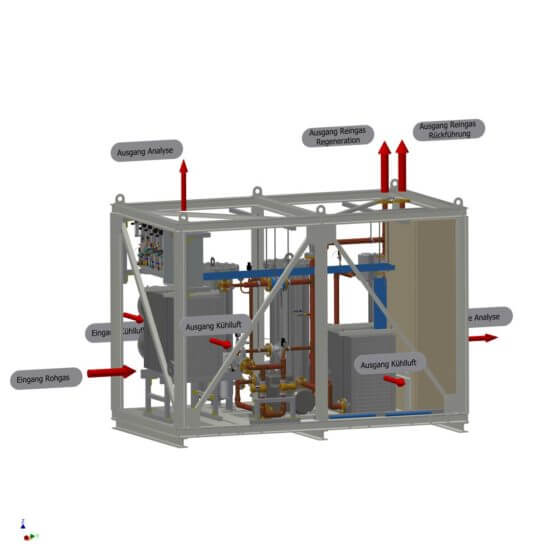

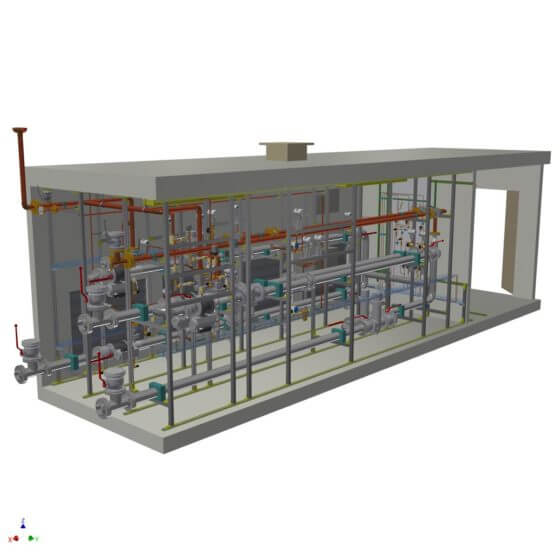

Gas mixers and gas mixing systems: technology, applications and importance in the industry

https://www.lt-gasetechnik.de/wp-content/uploads/2025/06/1738760795392-1024x576.png 1024 576 Walter Rodriguez Hernandez Walter Rodriguez Hernandez https://secure.gravatar.com/avatar/475aa8f2718077e4e1da0f43bc52ffbda843b5a13dd557bd431b20af6abe8516?s=96&d=mm&r=gGas mixers and gas mixing systems: precision, safety and versatility in industry Gas mixers and gas mixing systems are central components of numerous industrial processes that enable the precise and…

read more