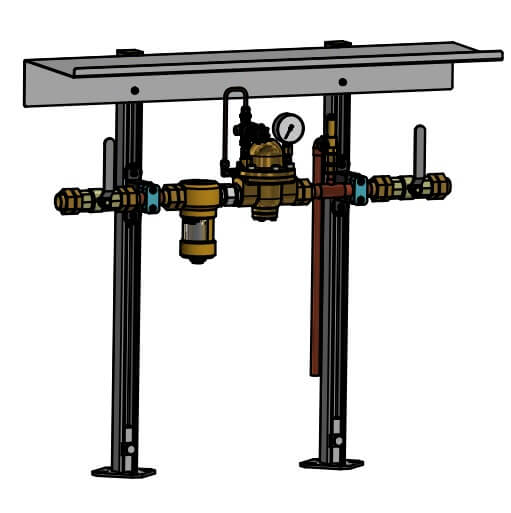

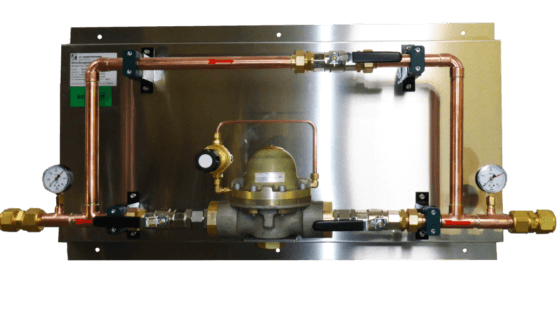

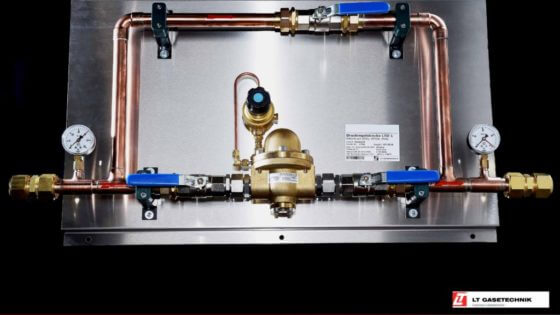

Modular system for LT pressure regulating lines

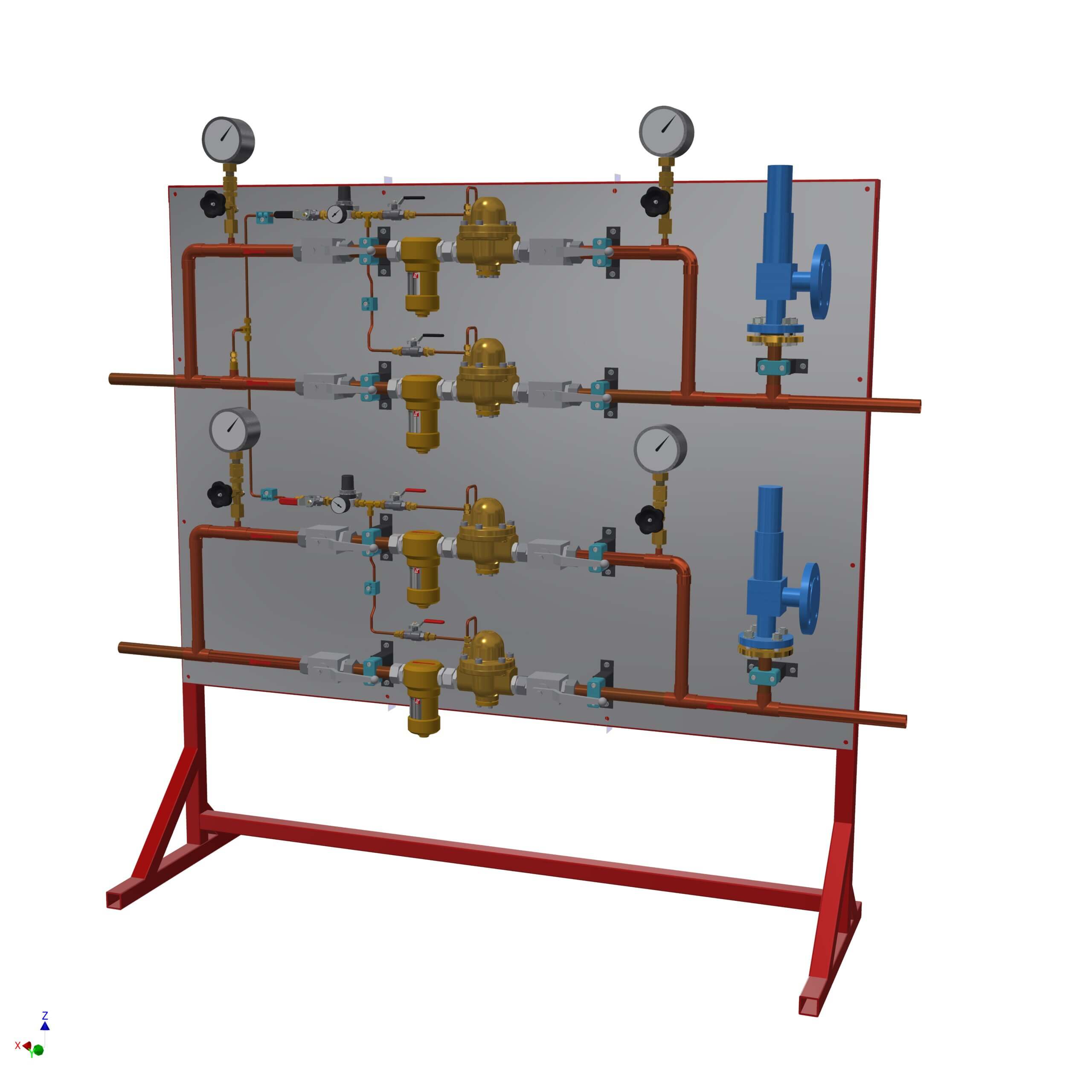

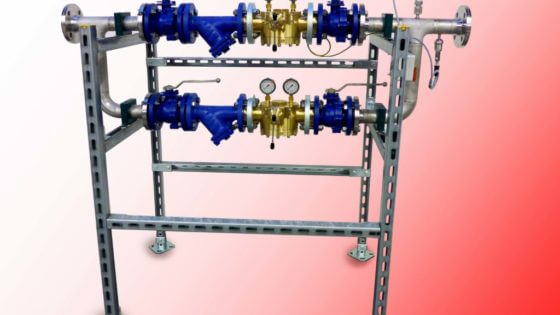

LT offers you a modular system for easily putting together a tailor-made solution for pressure control systems. We design compact and completely ready for connection and operation. Your pressure control system is individually priced, offered, manufactured and documented including certificates and operating instructions. This means you receive a finished, 100% pressure-tested and CE-compliant solution directly to your construction site to reduce setup and working time.

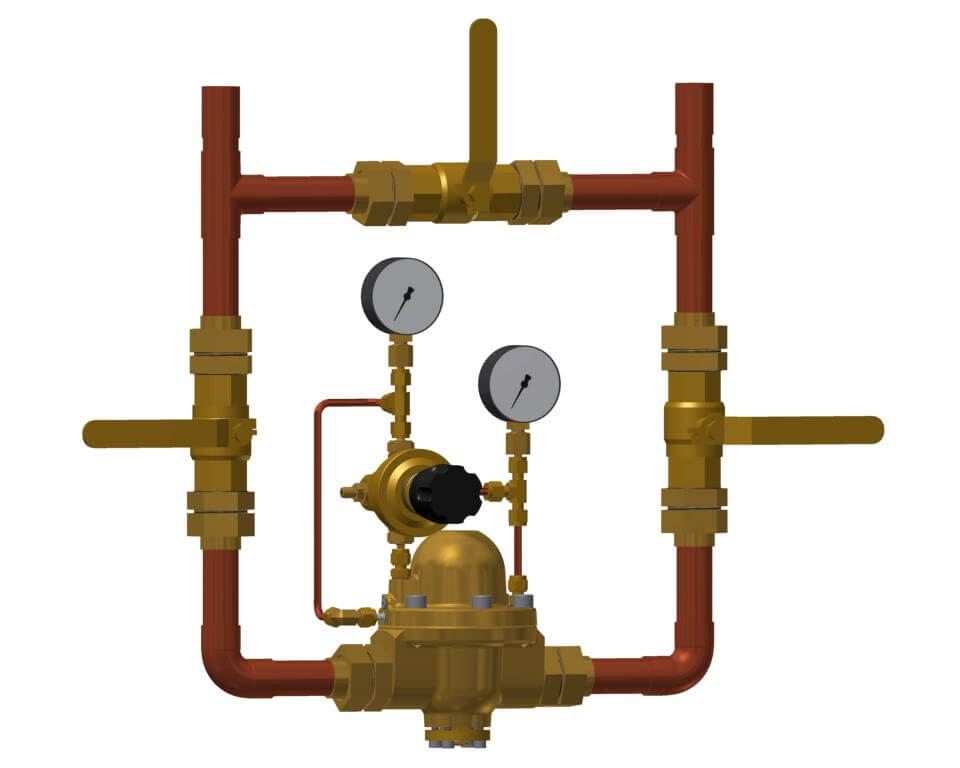

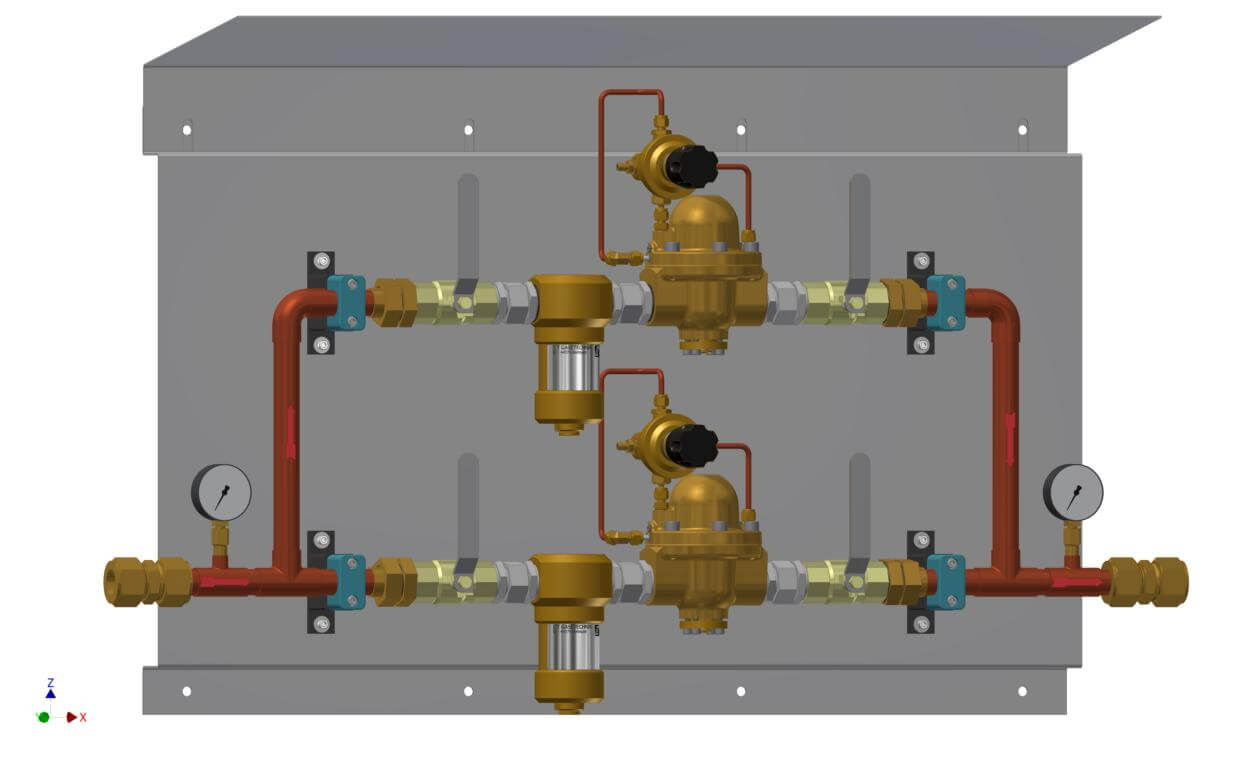

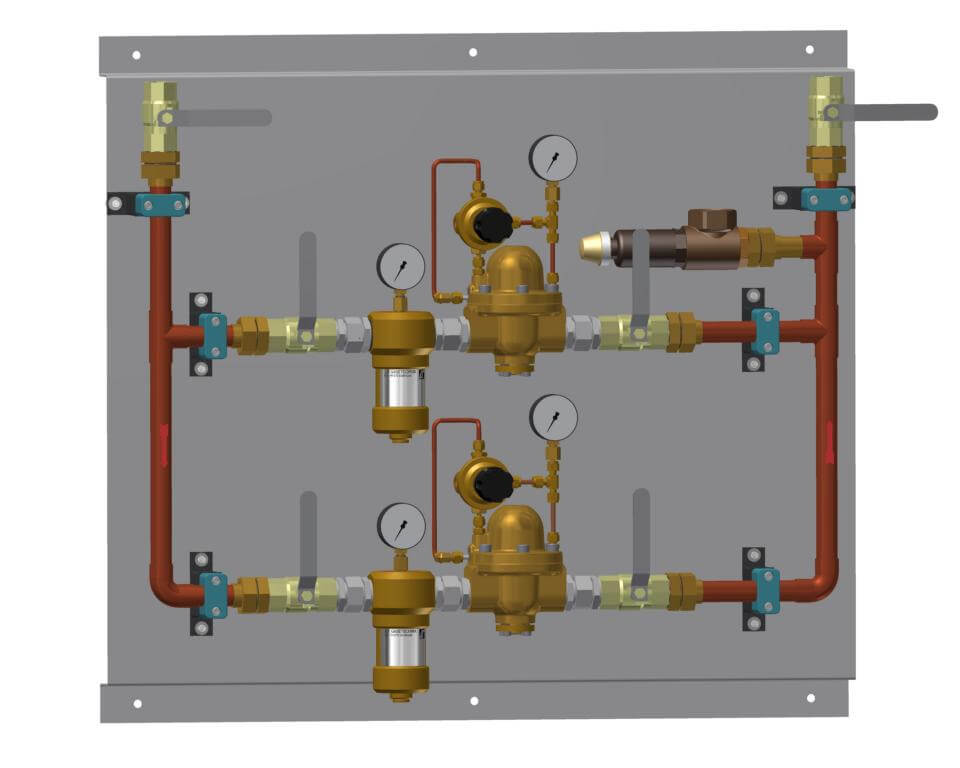

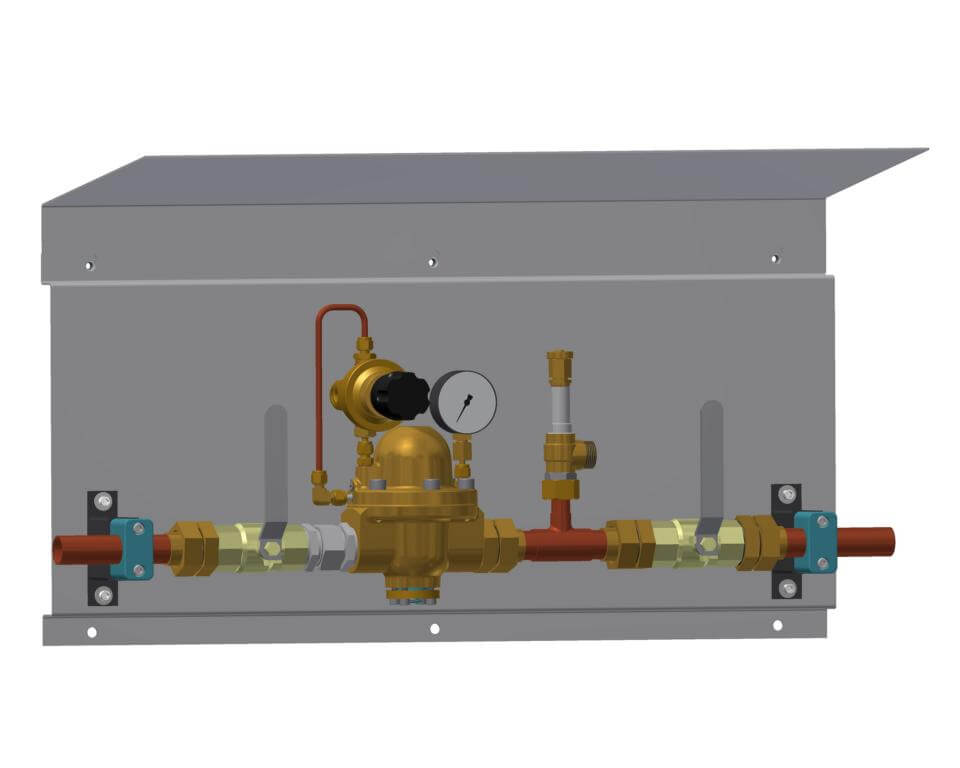

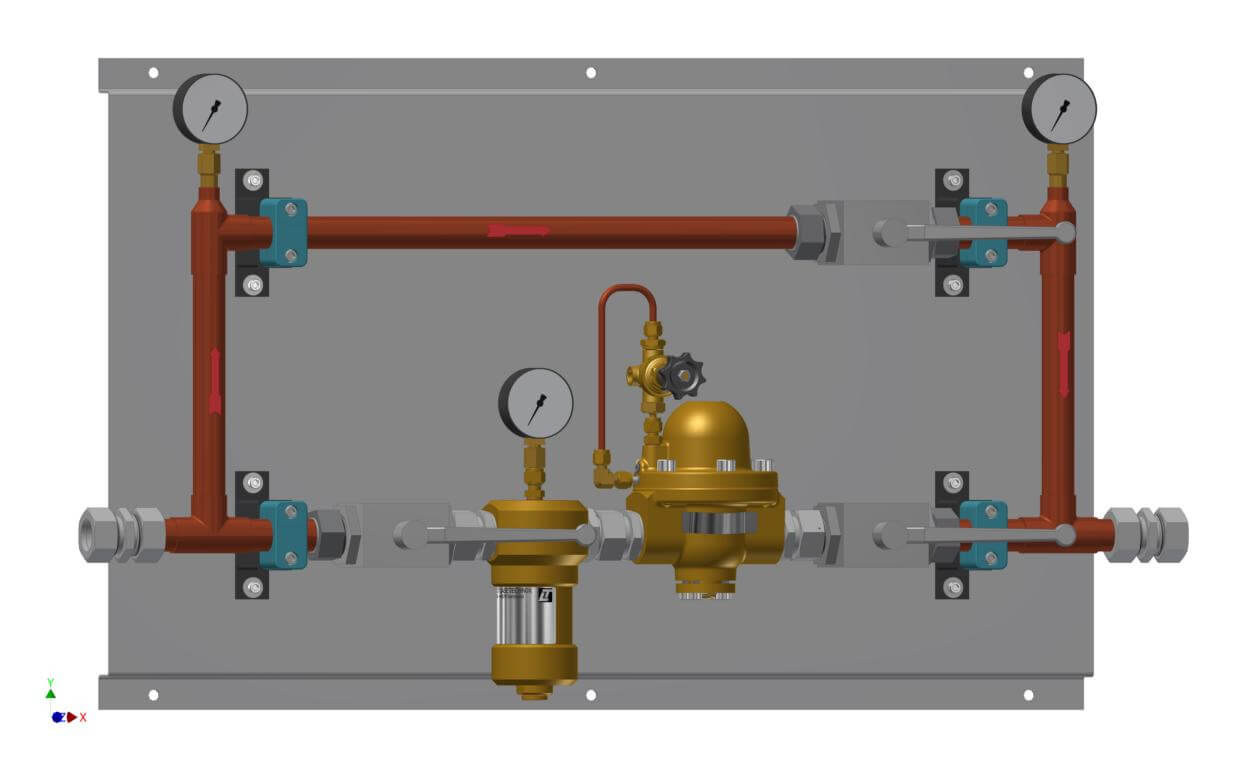

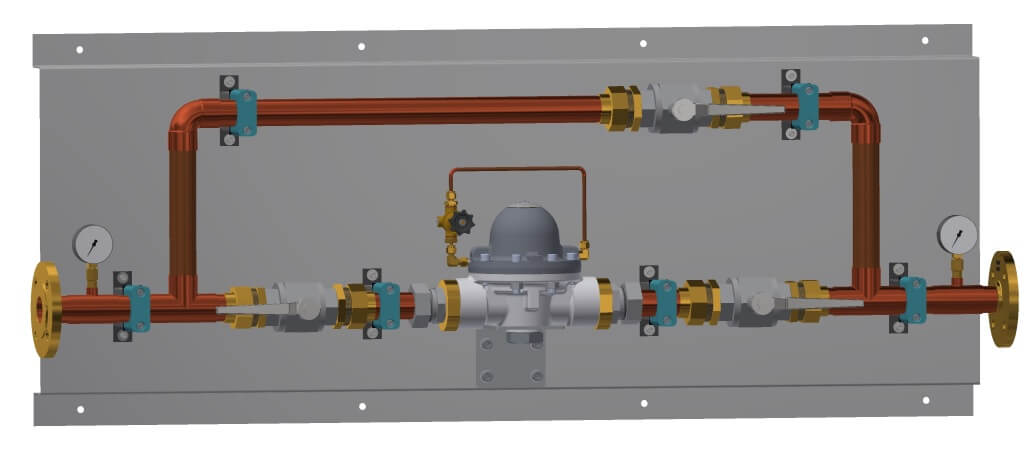

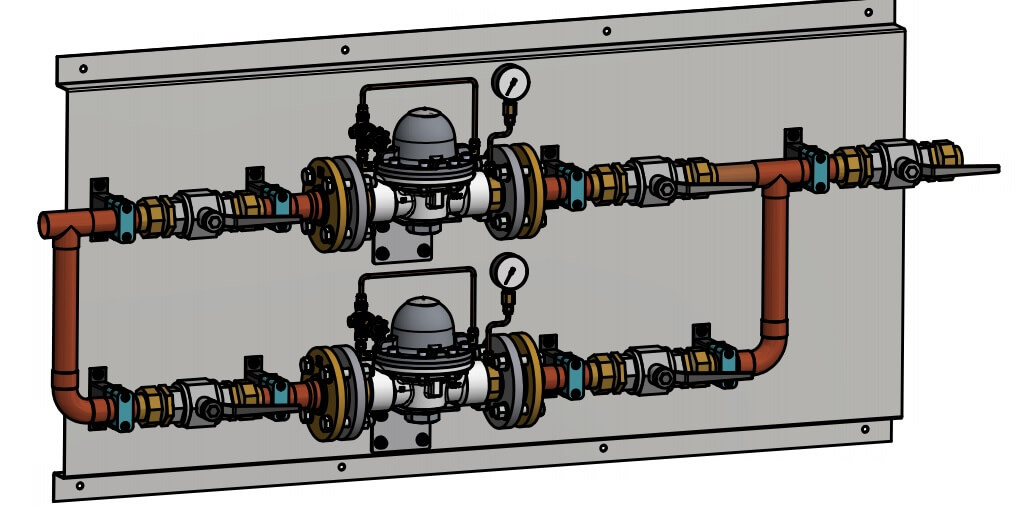

LT modular system:

- Piping: Soldered Copper or welded Stainless Steel

- Nominal size e.g. DN25, DN40, or DN50

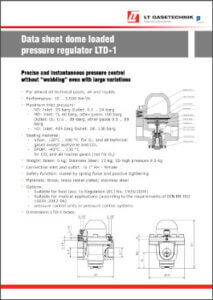

- Dome loaded pressure controller 1“ or 2“ BSP

- Gas type and pressure specific

- Connections: Soldering screw joint, flange, open pipe end, or compression fitting

- Ball valve(s): Inlet/outlet/bypass

- Gas filter/dirt trap – w/wo contamination indication

- Pressure control units type 1-12, as well in the bypass

- Inlet pressure and/or outlet pressure gauge in defined diameter w/wo shut-off valve

- Safety valve(es) per pressure controller/collective

- W/wo panel and/or stand for floor installation, w/wo roof

Other and bespoke solutions upon request. For example: 3″, aggressive/corrosive gases, connection positions (top, down, or sideways), flow direction (to the right or to the left), pressure transmitter w/wo local display, temperature transmitter w/wo sleeve, pressure-relief valve, gas analyzer connection, emergency feed point, certificate(s)

The proven dome loaded pressure controller LTD-1 or LTD-2 is available in different standard versions as pressure control panel: