Use of future green energy from H2 and CO2 by LT GASETECHNIK

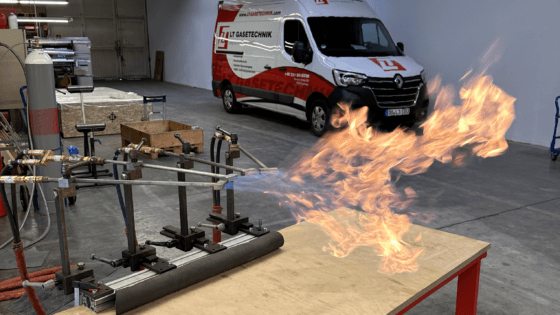

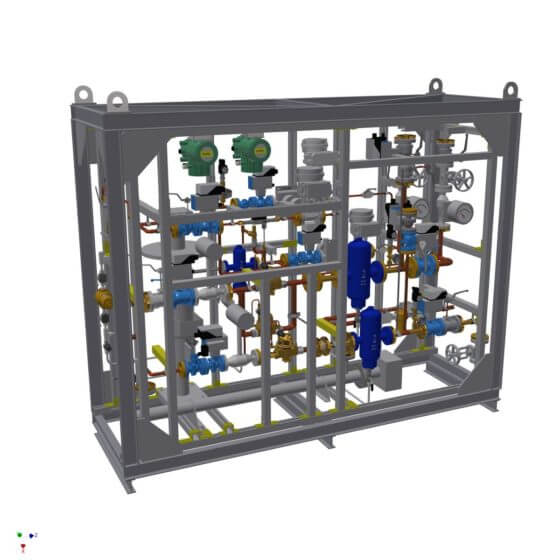

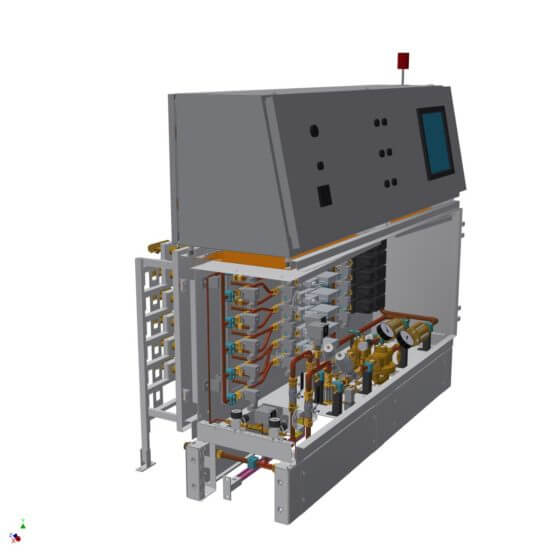

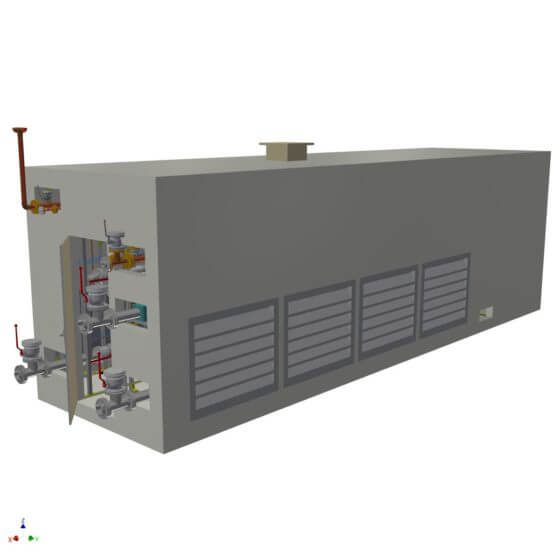

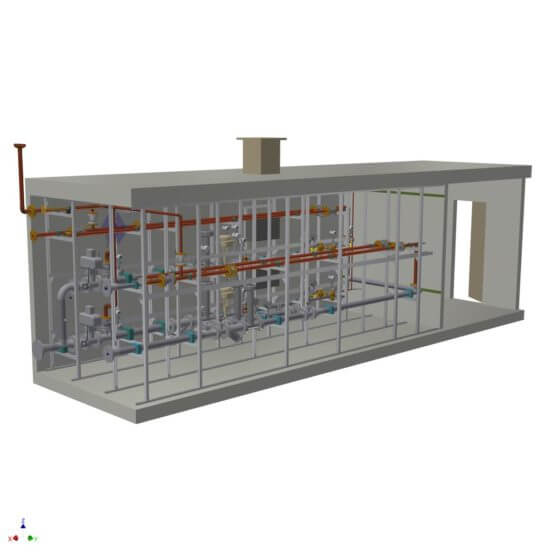

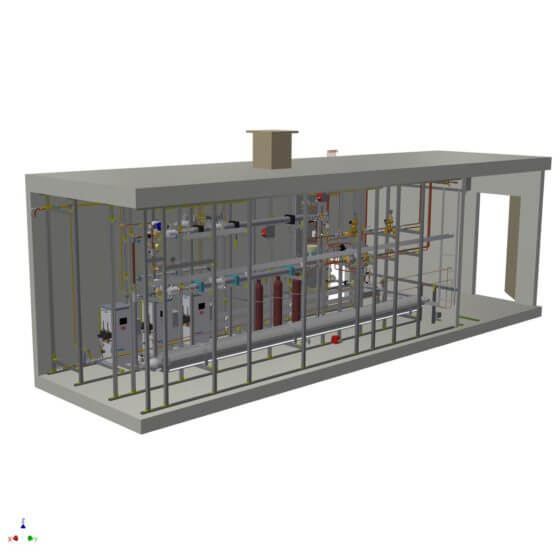

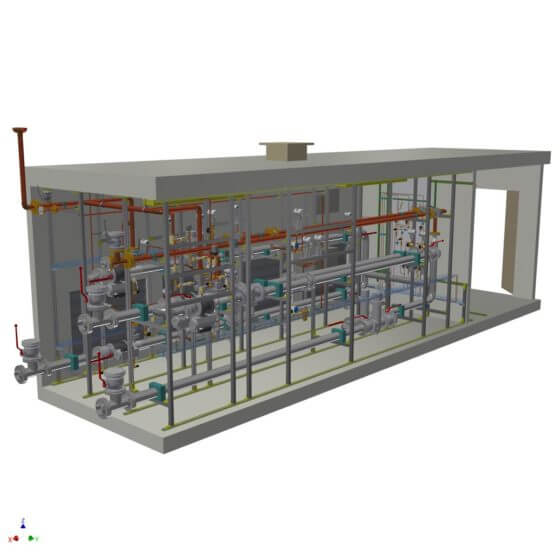

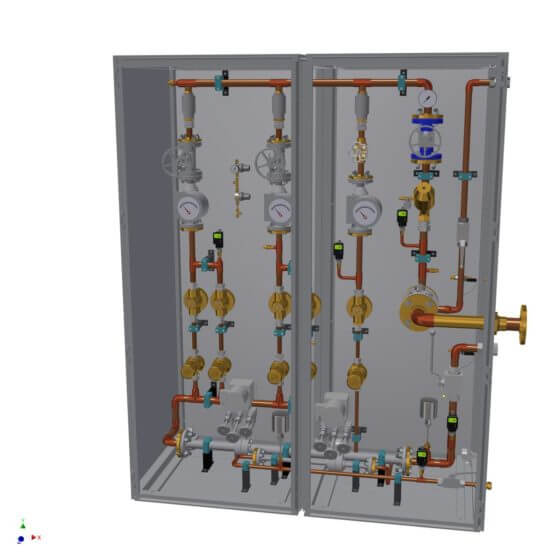

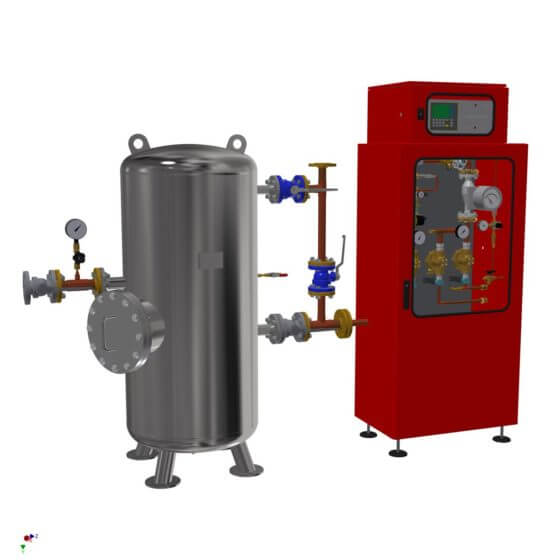

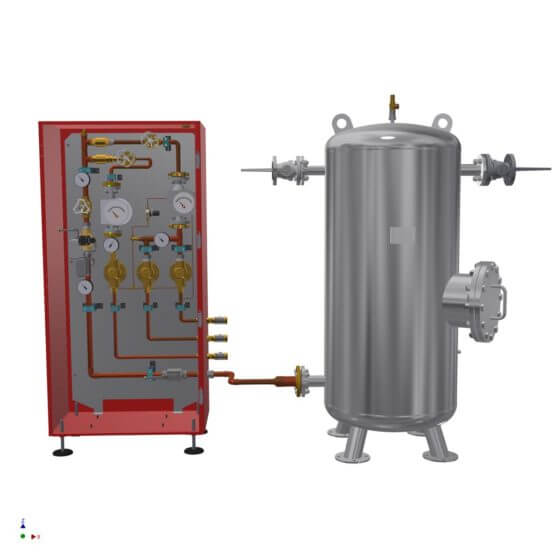

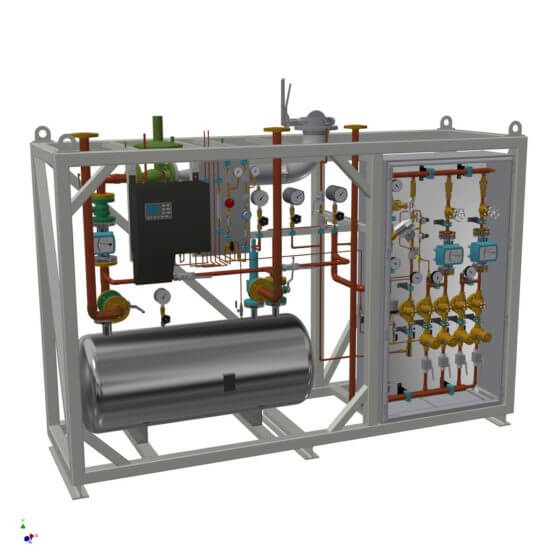

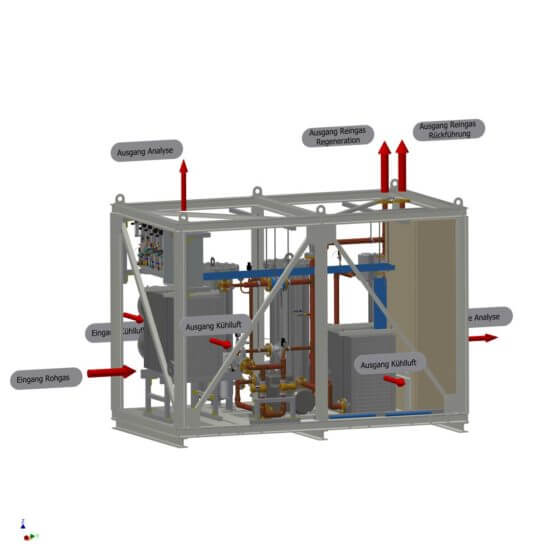

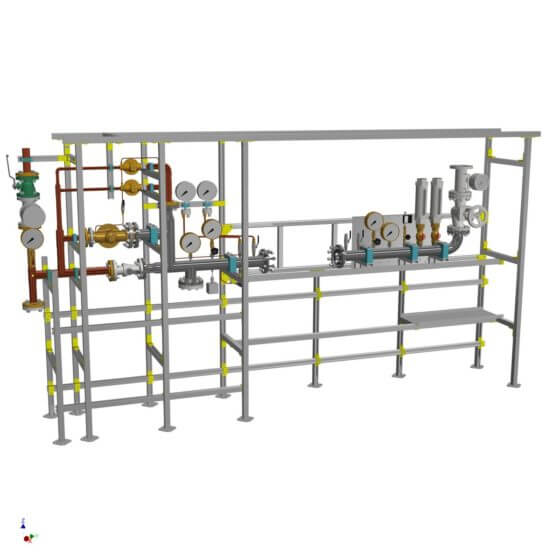

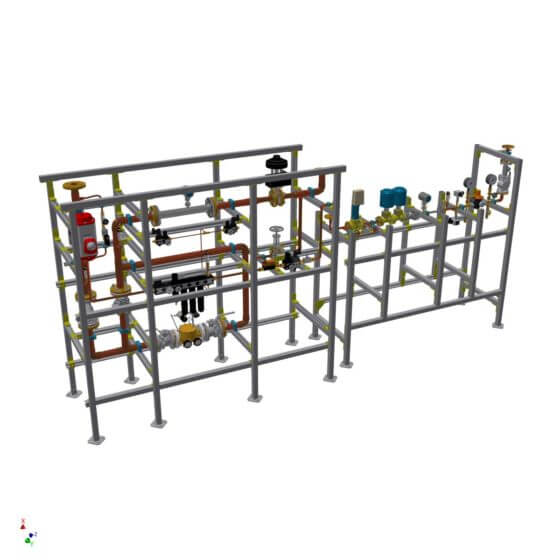

https://www.lt-gasetechnik.de/wp-content/uploads/2024/03/gasemischanlage_lt-gasetechnik-1024x578.jpg 1024 578 Alexander Hanf Alexander Hanf https://secure.gravatar.com/avatar/f89f4d10a36f5d89cef53cf152aa4130?s=96&d=mm&r=gVideo of a new LT gas mixing plant for the use of green hydrogen (#H2) and carbon dioxide (#CO2) in combination with natural gas

read more