Customized gas mixers for protective gases in the food and beverage industry

In order to prevent the loss of natural freshness and quality, modified atmospheres are often used in the food and beverage industry (modified atmosphere packaging – MAP). With the help of natural gases, the quality of the food is preserved and its shelf life improved. A wide variety of gas mixtures are used for this purpose, which can be produced in LT gas mixers. Z. B.:

- Raw red meat or raw dark poultry: O2 andCO2 (oxygen and carbon dioxide)

- Raw white meat, cooked meat or sausages:CO2andN2 (carbon dioxide and nitrogen)

- Raw fish:CO2, O2andN2( carbon dioxide, oxygen and nitrogen)

- Smoked fish, cooked fish, crabs/shrimps:CO2andN2( carbon dioxide and nitrogen)

- Hard cheese, soft cheese, yoghurt:CO2andN2( carbon dioxide and nitrogen)

- Vegetables, salads: O2,CO2 and N2 (oxygen, carbon dioxide and nitrogen)

- Beer, sparkling wine, sparkling wines:CO2andN2( carbon dioxide and nitrogen)

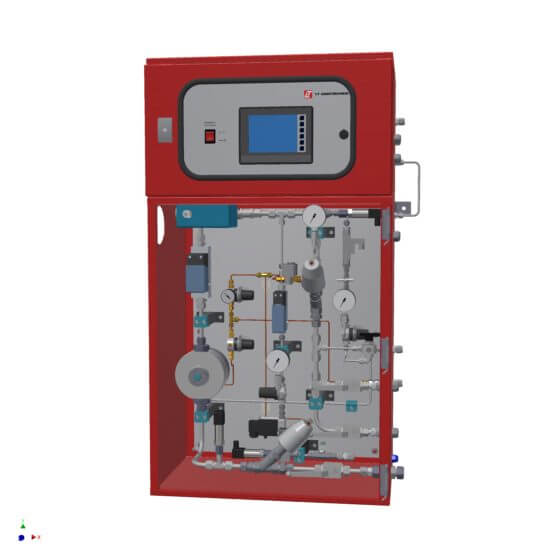

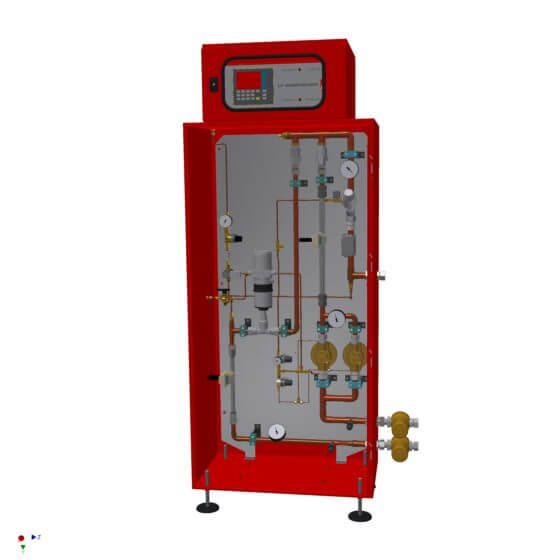

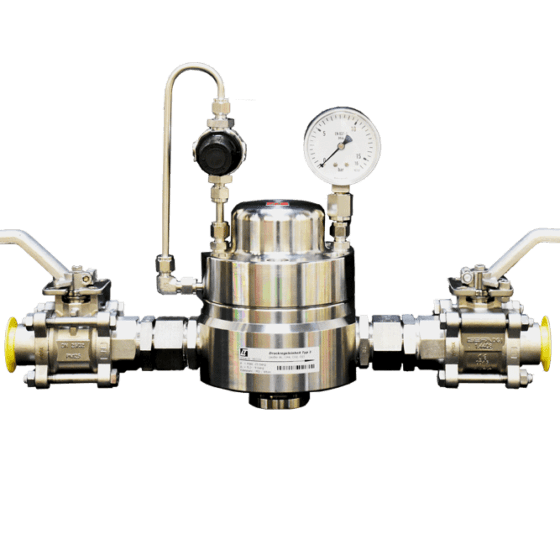

LT GASETECHNIK’s standard gas mixers for two or three gases for the food and beverage industry have a capacity of a few liters per minute (Nl/min) up to 500 cubic meters per hour (Nm³/h) and are optionally available as

- with or without buffer tank

- with or without gas analysis system

- as static gas mixers with manual control or

- as dynamic gas mixers with fully automatic control with MFC (mass flow controller)

executed. For dynamic gas mixers with an analysis system, the process data, alarm signals and fault messages are usually displayed on an operator panel and, if required, transferred to the customer’s process control system.