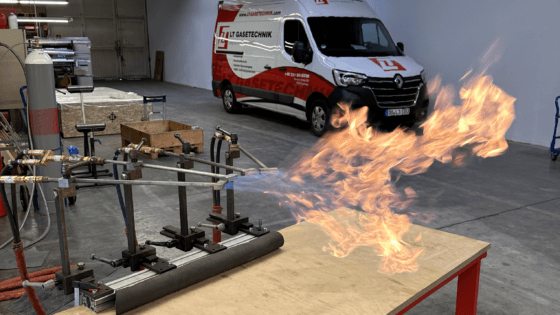

H2 and methane – different flame patterns

https://www.lt-gasetechnik.de/wp-content/uploads/2024/01/gasemischer_video-1024x578.png 1024 578 Alexander Hanf Alexander Hanf https://secure.gravatar.com/avatar/f89f4d10a36f5d89cef53cf152aa4130?s=96&d=mm&r=gIn this fascinating video, we show the differences in the flames of hydrogen (H2) and natural gas (methane, CH4), each mixed with oxygen. The different properties and appearance of the…

read more