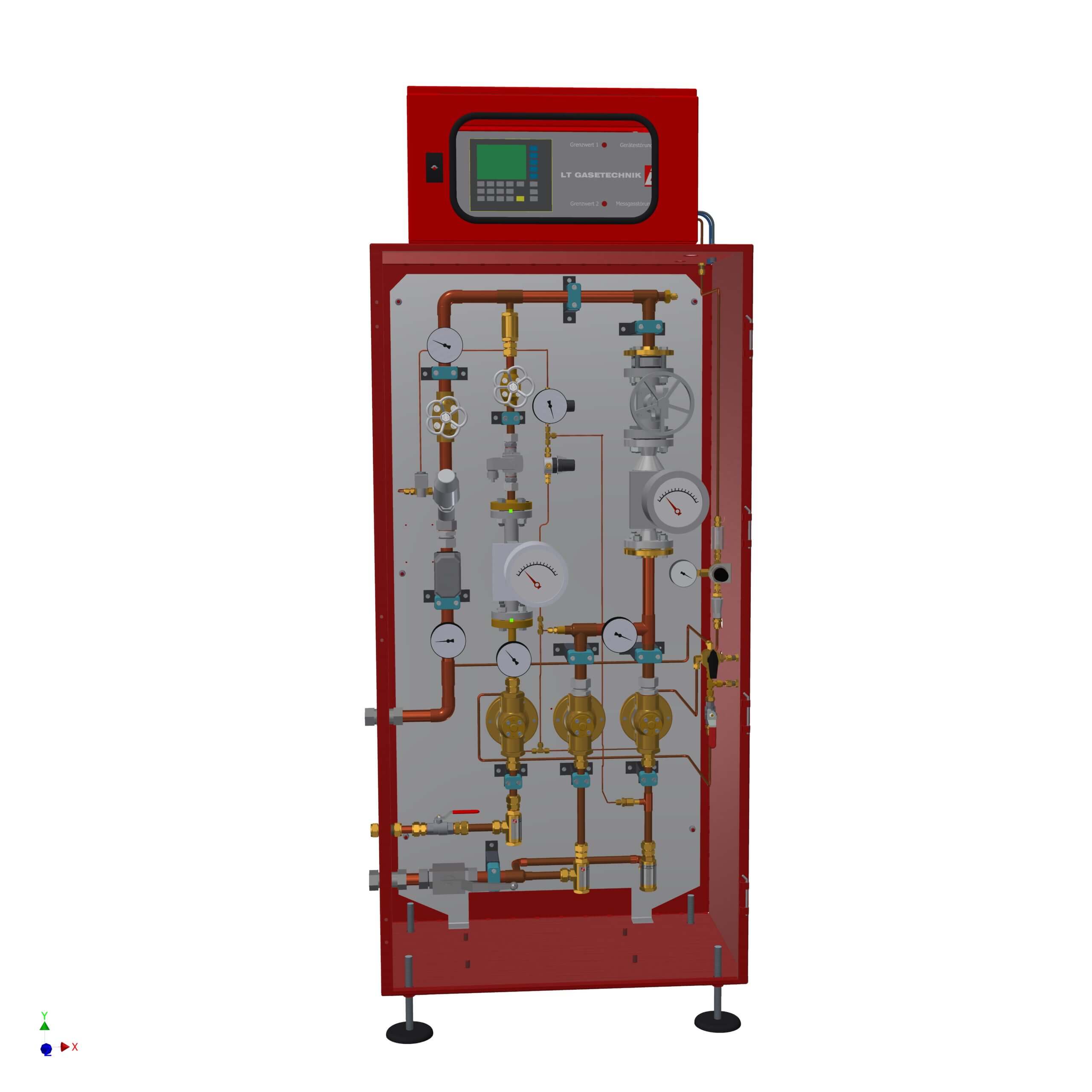

If you use a gas mixer, choose a really accurate one, this will save (in a typical case) 30% of the Hydrogen costs!

https://www.lt-gasetechnik.de/wp-content/uploads/2021/03/reducing-operating-costs-1.jpg 878 494 Alexander Hanf Alexander Hanf https://secure.gravatar.com/avatar/f89f4d10a36f5d89cef53cf152aa4130?s=96&d=mm&r=gThe reason for this significant saving potential is a question of arithmetic: Here is an example: In this example the product quality will fluctuate and get worse if there are…

read more