Magerluft mit SIL-2

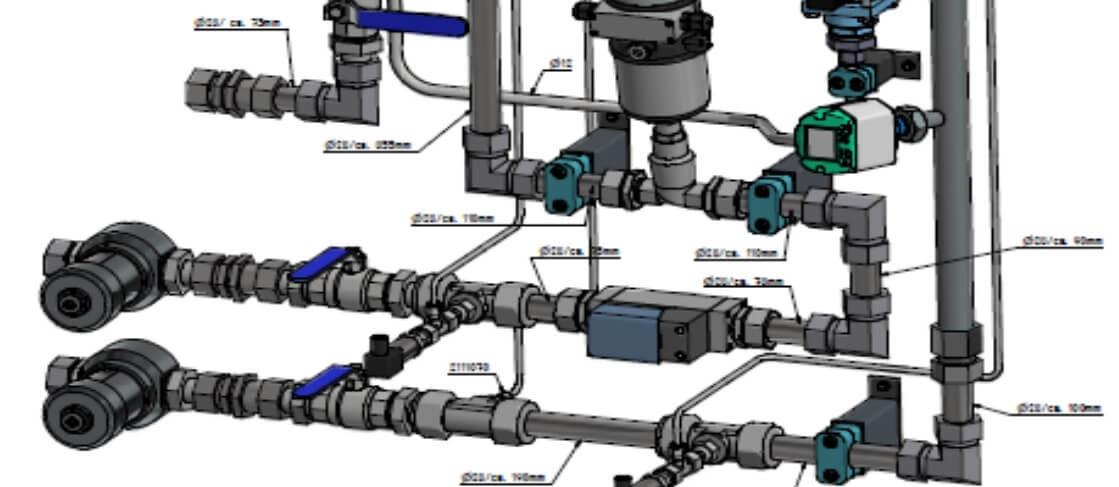

LT again successfully delivers a lean air system. The system can generate 200 Nm³/h of synthetic air from nitrogen and compressed air. Of these, approx. 50 Nm³/h are used for pigging for approx. 5 minutes and 130 Nm³/h for approx. 30 minutes for inerting.

The produced lean air shall have an oxygen content of 6% in the gas mixture (this is how the name “lean air” comes about, because the oxygen content in relation to normal breathing air with approx. 20.9% is reduced or leaned to 6%). . Lean air is often used in processes for supplying solvent boilers and reactors, e.g. required in the production of synthetic resins (also called resins). These processes can lead to explosions or deflagrations. Overlaying the product with lean air during manufacture prevents this. With this application, compliance with the oxygen content specified for the lean air is essential for safety-related issues. This is why a gas analyzer is used for oxygen concentration monitoring with safe shutdown when limit values are exceeded. The gas analyzer and shutdown have safety integrity level 2 (SIL-2).

We look forward to receiving your inquiry on the subject of “Lean air with SIL-2”: mail@lt-gasetechnik.com