SO 2 in breathing air

Sulfur dioxide concentrations in breathing air that are above the maximum workplace concentration of 2.7 mg/m³ sulfur dioxide (SO2) in air can lead to headaches, nausea and drowsiness in humans. At higher concentrations, the bronchi and lungs are severely damaged.

SO2 bottles are often stored indoors for temperature control, also directly next to thermoprocessing plants, sometimes without any occupational safety measures. To protect the health of employees and to meet the requirements of the Occupational Health and Safety Act, however, SO2 bottles must be kept in a suitable storage facility. As part of the risk assessment in accordance with Section 5 of the German Occupational Health and Safety Act and Section 6 of the GefStoffV (German Ordinance on Hazardous Substances), the employer must determine whether the storage of hazardous substances can endanger employees or other persons.

(German) rules:

In Germany the following rules have to be complied with

- TRGS 510 Storage of hazrdous materials in transportable equipment

- TRBS 3145 / TRGS 745 Portable compressed gas containers – filling, providing, in-house transport, emptying

- TRBS 3146 / TRGS 726 Fixed pressure systems for gases

The safety data sheet “Sulfur dioxide – SO2 liquefied under pressure” says:

- H280 – Contains gas under pressure, may explode if heated

H314 – Causes serious irritation of the skin and serious eye damage

H331 – Toxic if inhaled

- Storage separate from flammable substances

P403 – Keep in a well-ventilated place

P405 – Store locked up

Storage facilities

A suitable storage device is an appropriately designed SO2 cabinet.

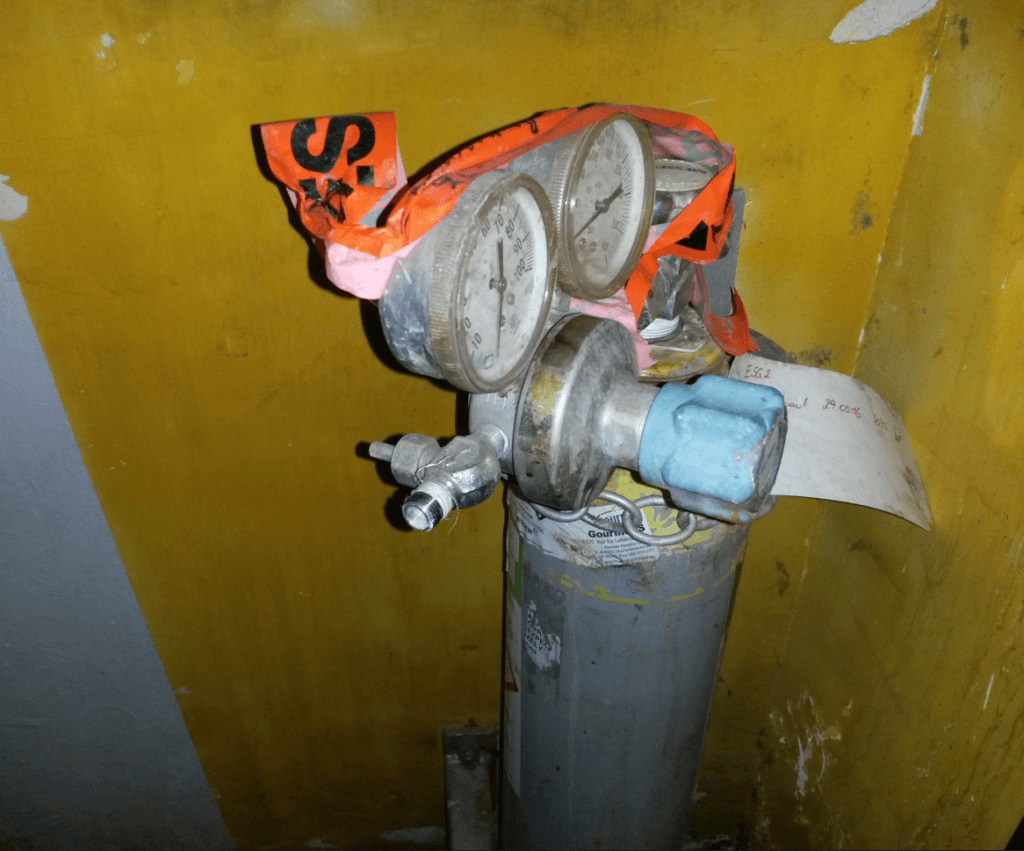

Not suitable is the installation shown in the example picture – a practice that unfortunately also lives in Western Europe, while accepting health damage among the employees:

Design

Design

The typical design of a suitable SO2 cabinet consists of:

- Safety gas bottle cabinet for three SO2 (50 l each) and one N2 bottle (10 l)

Two bottles of SO2 are installed for operation and automatic change-over, one bottle is in the cabinet for pre-tempering. The N2 bottle is used to supply the flushing device for a safe bottle change. - Designed as a 30-minute fire-retardant cabinet, as the gas under pressure can explode when heated, causing severe skin burns and eye damage.

- The cabinet can be locked because the safety data sheet for sulfur dioxide also specifies “P405 – Keep locked up”.

- The use of particularly high-quality fittings in stainless steel is standard, since SO2 is converted to sulfuric acid (H2SO4) with atmospheric moisture. The detailed picture shows the stainless steel version:

- SO2 pressure control station made of stainless steel with automatic change-over, for uninterrupted media supply. For connecting two SO2 gas bottles with external gas flushing and bottle connection hose (stainless steel corrugated hose)

- Automatic stainless steel shut-off solenoid valve (NC) to shut off the SO2 process line to the point of use in the event of an emergency stop or gas alarm

- Gas warning sensor

- Forced ventilation on request and when the gas warning device is activated to be connected to a ventilation system

- Emergency stop button and optical / acoustic signal

In addition, gas warning sensors can be attached to the thermoprocessing plant(s) near the points of use, which are also connected to the central gas warning center. Optical/acoustic signaling should be installed close to each point of use.

In this way, employees are safely protected against the risk of excessive SO2 concentrations in the breathing air and against burns in the event of accidents. At the same time, the uninterrupted and thus secure process supply is guaranteed.

Design

Design