Turbo generators are cooled with hydrogen due to its better cooling properties – hydrogen-carrying parts of the plant require attention with the aim of safe handling of the gases to protect employees and plant technology.

LT GASETECHNIK examines, improves and modernizes fixed installations for the hydrogen supply in power plants and for the generator supply. We plan the handling of these gases and supply the associated technology:

- Pressure control stations

- Automatic switching stations

- Safety and gas measuring devices

- Safety concept and explosion protection document

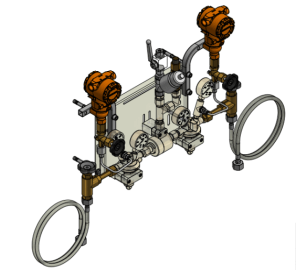

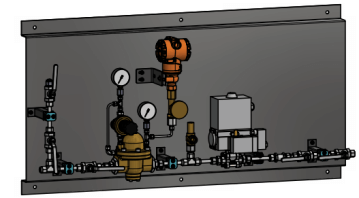

Project example:

Overview complete system Automatic bundle switching station Main pressure control station

As a preliminary stage, the equipment can be checked against the current standards. LT offers this as external expert, safety study according

- Pressure Equipment Directive

- ATEX

- Industrial safety ordinance in connection with TRBS and TRGS

From our works in Dortmund, Germany, you receive from a single source:

- Safety study, consulting

- Concept and detail engineering for the mechanical part

- Engineering, design and programming of the measurement, control and automation system including gas analysis technology

- Manufacturing, testing and commissioning of the systems

- Documentation with CE marking, risk analysis, HAZOP study, possibly SIL classification