Advancing the energy transition while avoiding the natural gas shortage

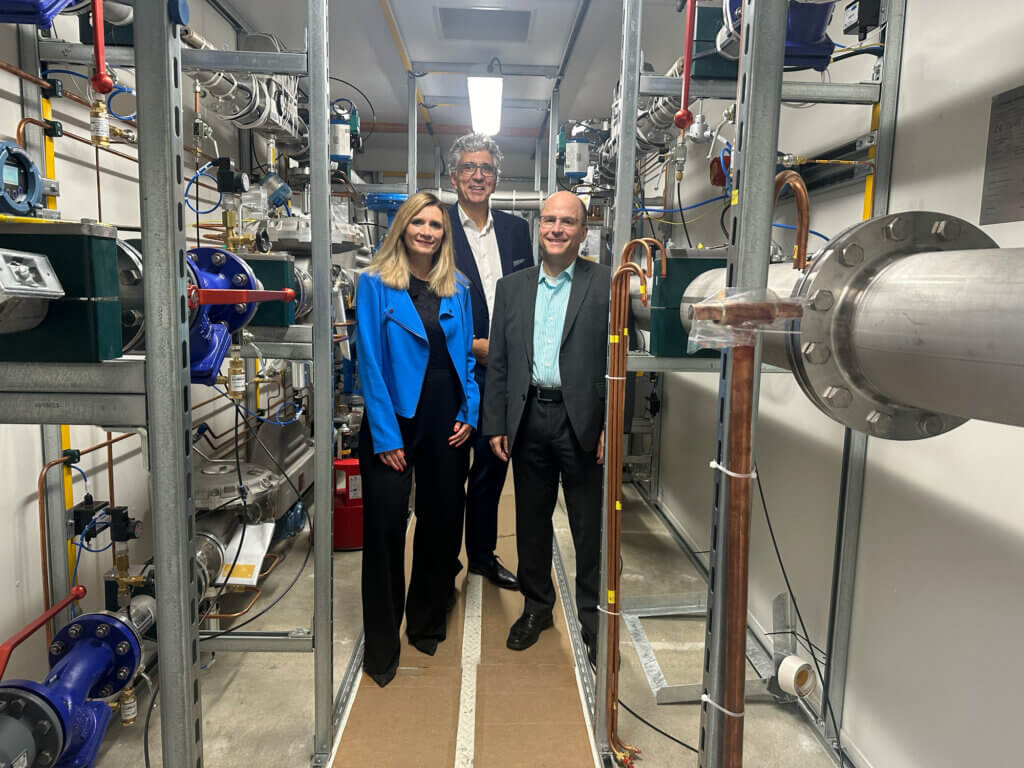

Dr. Laura Dorfer, Managing Director, and Stefan Oberdörfer, expert at the VDMA Welding and Compressed Gas Technology Association, visit LT GASETECHNIK. We also exchanged views on the trend topic of hydrogen. During the guided tour of the company, the VDMA got an idea of plants that offer a tailor-made solution for gas mixing and can serve not only as a fully automated back-up, but also as a possibility for a smooth transition to the use of hydrogen. As a result, the plants offer a safe and efficient way to reduce dependence on natural gas and diversify the energy supply.

In the background of the photo you can see a tailor-made system specially designed for gas mixing. This plant not only serves as a fully automated back-up, but also offers the possibility of a seamless transition to the increased use of hydrogen.

During the visit, we were able to show live the wide range of equipment available. From smaller units with an output of 120 Nm³/h (approx. 2 MW) to gas mixing plants for large outputs with over 5,000 Nm³/h (approx. 90 MW), some gas mixing plants were in various production stages.

What makes these systems stand out are their sophisticated SIL-2 monitoring and shutdowns. As a result, they not only ensure the highest safety standards, but also remarkable accuracy and reproducibility in the production of gas mixtures. Thus, the gas mixing plants offer a safe and efficient way to reduce dependence on natural gas and diversify the energy supply. In times of the energy transition, technologies such as these are an important step towards shaping a sustainable and future-oriented energy supply.