In order to prepare for a natural gas shortage, our customer uses an LT gas mixing plant for propane/air. This plant can mix propane and air to form a natural gas substitute (SNG) and feed it into the plant network instead of natural gas. The commissioning of the gas mixing plant has been successfully completed.

Propane gas has a significantly higher calorific value than natural gas. However, the existing burners cannot process propane without being rebuilt or replaced. This would cause downtime and costs. Therefore, in the LT gas mixing plant, propane is mixed with compressed air to achieve the calorific value of natural gas. This customer-specific plant has a capacity of 42.1 MW and can generate up to 2,548 Nm³/h propane/air-gas mixture with a Wobbe index of 13.4…14.8 kWh/Nm³.

The system is qualified according to DIN EN 61882 according to HAZOP study and has extensive safety measures, e.g. a gas warning system, differential pressure monitoring and SIL-2 circuit, including an oxygen gas analyzer and shutdown. Thus,

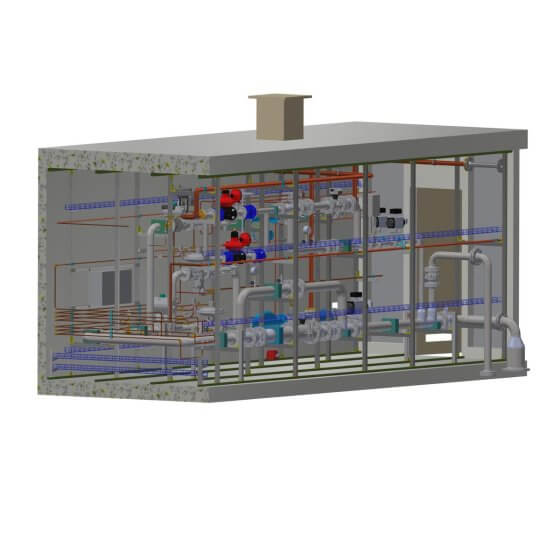

The installation takes place in an insulated 30-foot container, with Siemens S7 control for regulating flow and the solenoid valves in a closed control loop as well as for displaying all measured values, alarms and status messages on the local touch screen. A Wobbe index analyzer provides a continuous reading of the calorific value of the gas mixture.

In this way, our customer has support in the supply of SNG, especially in the event of a natural gas shortage, and flexibility is achieved with regard to energy prices. In addition, hydrogen can also be added to these gas mixing plants (after appropriate retrofitting). For industrial companies, the switch to a partial supply of green hydrogen means energy flexibility using existing installations. In addition to additional security of supply, this is also associated with the possibility of price optimization.

The LT gas mixing plant is a safe and efficient way to reduce dependence on natural gas and diversify the energy supply. It therefore offers the following advantages:

- Reduced dependence on natural gas

- Potential to reduce energy costs

- Improved energy flexibility

- Possibility of hydrogen admixture and thus reduced CO2 emissions

Do you want to know more about LT gas mixing plants? Contact us: SNG@LTGas.de