No carnival at LT GASETECHNIK

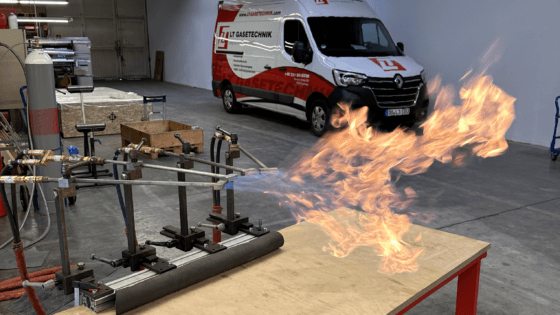

https://www.lt-gasetechnik.de/wp-content/uploads/2023/02/SNG-Blick-in-Fertigung-mit-Mueller-1024x461.jpeg 1024 461 Alexander Hanf Alexander Hanf https://secure.gravatar.com/avatar/db2b524fb591574d36b6f1c5af0218f7a6af4a228530c02a586d1be61f1d05c4?s=96&d=mm&r=gWhat does carnival look like at LT GASETECHNIK? Instead of celebrating carnival, our superheroes ♂️♂️♂️ are hitting the weekend and finishing off gas mixers. Thanks guys for your commitment , I’m proud of you! This is what carnival looks like at LT GASETECHNIK! The six red gas mixers are each designed…

read more